When it comes to heavy lifting, overhead cranes are a must. Whether you are constructing a bridge or moving heavy objects, having the right crane for the job is essential.

This post will look at some of the most important considerations when hiring an overhead crane.

Essential Considerations Before Hiring Overhead Cranes

Matching the Crane to the Site

The first thing you should consider when hiring an overhead crane is whether it matches your site. You will need to consider factors such as height clearance and work area size to ensure that the crane can fit into your space and perform its job effectively.

It’s also important to consider how much weight you’ll be lifting – if it’s too heavy for the crane, it could cause serious damage and put people at risk.

Cautiousness is the Best Approach

When operating an overhead crane, safety should always be your top priority. Ensure all operators are trained and certified following local regulations and industry standards before allowing them to operate any machinery onsite.

Additionally, inspect all crane components before use and conduct regular maintenance checks throughout its operation. Doing so will help ensure that everyone remains safe throughout the process.

Be Aware of Licencing and Safety Requirements

It’s important to be aware of any applicable licensing or safety requirements associated with operating an overhead crane in your area before you begin using one. In most cases, certain regulations must be complied with to operate a crane onsite legally. Make sure you understand these and ensure they’re being met at all times during operations. Additionally, keep up-to-date with any changes in safety regulations so that you can stay compliant.

Align Speed With Safety

Speed is key when operating an overhead crane, but safety should always come first! Ensure that all operators understand how quickly they can safely move using a crane without compromising their safety or those around them. Additionally, check regularly for any signs of wear or fatigue on components such as cables or pulleys, which could lead to accidents if not addressed immediately.

Accessories That Can Make Your Project a Reality

Many different accessories are available for overhead cranes, which can help your project run more smoothly and efficiently than ever before.

Some popular options include hoists, jibs, trolleys and spreaders, which can help increase productivity by allowing multiple tasks to be completed at once; make sure you understand how each accessory works before attempting operations onsite.

Additionally, look into customising your equipment with additional attachments such as magnets or hooks, which can further enhance performance depending on what type of project you’re working on.

Crane Hire Costs

Finally, remember costs when hiring an overhead crane. Make sure you clearly understand what fees may apply (such as delivery charges) and any ongoing maintenance costs associated with keeping up functionality over time.

It’s important to have a full picture, so your budget isn’t suddenly thrown off track mid-project due to unforeseen expenses.

When to Hire an Overhead Crane

Whether you’re looking for short-term rental services or long-term leasing options, plenty of options are available regardless of your budget or industry needs. Hiring an overhead crane is a great way to increase safety and efficiency while reducing costs simultaneously. It can help improve productivity on job sites while eliminating any risks associated with manual labour or expensive machinery purchases/maintenance costs down the line.

Safety Benefits

The first and most important benefit of hiring an overhead crane is safety. With the proper equipment, manually lifting heavy items can be safe for employees, both physically and mentally.

With an overhead crane, there’s no need for manual labour; the crane can handle all of the hard work with ease. It eliminates any potential risks associated with manual labour and ensures that each job is done safely every time. Plus, it can help protect your business from unnecessary liabilities in case of accidents or injuries on the job site.

Cost Savings

With a single piece of equipment handling all the heavy lifting equipment needs, purchasing multiple machines or hiring additional staff to manage them is unnecessary. Hiring on a long-term basis can lead to significant cost savings in terms of money and time spent managing multiple machinery pieces. Hiring an overhead crane can also provide cost savings over time as it eliminates any potential maintenance costs associated with owning and operating one yourself.

Time Savings

Finally, hiring an overhead crane will also save you time in the long run. Not only does it reduce manual labour times dramatically, but it also allows for faster loading and unloading times overall when compared to traditional methods like forklifts or cranes without hoists attached.

Additionally, since they require minimal training or instruction before use, they can be easily operated by anyone who knows how to use them properly—saving even more time in training new staff members on complicated machinery operations.

Final Thoughts

There is much more than meets the eye when hiring overhead cranes for projects such as construction sites or factories. From matching speeds with safety requirements to carefully assessing costs associated with the delivery and upkeep, proper planning and; cautionary measures are essential when considering this powerful piece of equipment!

By considering all necessary considerations beforehand, professionals looking towards using an overhead crane can rest assured knowing their projects will run smoothly and; safely like clockwork every single time!

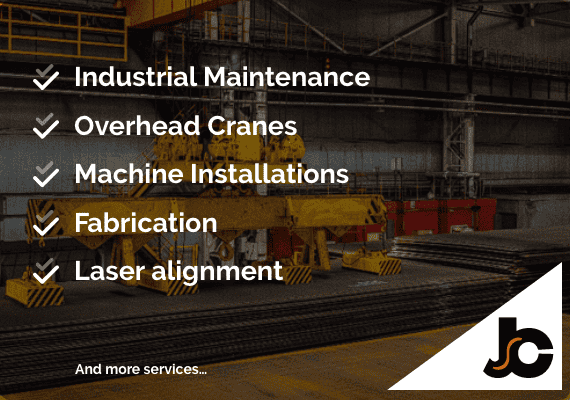

About Jones Complete Services

At Jones Complete Services, we understand first-hand how important an overhead crane or hoist is to your production. We recognise that downtime means lost productivity. Regular maintenance and servicing can significantly reduce the risk of downtime or injury to your staff.

We aim to get your overhead crane up and running as quickly and safely as possible while complying with Australian Standards and regulations. Our team ensures that your overhead crane offers the highest reliability and productivity, working at optimum efficiency.

The team at Jones Complete Services have built a reputation as Illawarra’s go-to team for Overhead Crane maintenance, repairs and compliance.

CONTACT US today to learn more about what services we can offer.

Frequently Asked Questions

What Are the Types of Overhead Cranes?

Overhead cranes are a lifting solution for transferring heavy items from one place to another. There are various overhead cranes, each with benefits and uses in different industrial applications.

- For example, gantry cranes feature tall bridges running along the length of tracks mounted on the ground or floor to provide support and stability when lifting objects.

- Double girder overhead cranes have two metal beams mounted on vertical columns featuring motors equipment with a chain mounted on top that is used to move the crane system up, down, and side-to-side.

- Wire rope hoists are equipped with steel ropes, sheaves, and drums that transfer electrical power to reduce motor load while providing smooth operation.

- Jib cranes feature stable steel structures that allow loads to be elevated from one point to range up to another.

- Electric chain hoists are designed for relatively small capacity lifts and often use pull chains which lift loads using an electric trolley hoist for engineering purposes.

- Lastly, workstation cranes provide rotating platforms for smoother turning movements of items around its base using electric motors and manually operated tools like winches, lanyards and hooks.

Each type of overhead crane offers greater efficiency than manual labour, making it a preferred choice for many industrial operations.

What Is the Use of Overhead Crane?

Overhead cranes are essential lifting solutions used in various industries to handle heavy loads safely. Often referred to as bridge cranes, these industrial crane systems can be mounted on an existing structure or suspended from another support. They allow heavy materials like engine blocks and steel pipes to be lifted and lowered safely from one place to another.

An overhead crane offers great flexibility for operators since it can move up, down, and sideways and rotate completely around its axis to pick up or deliver materials wherever needed. Sometimes, the system may also lower items into a container below.

What Are the Basic Components of an Overhead Crane?

Overhead cranes are essential equipment for many manufacturing and construction sites, providing a safe and cost-effective way to move heavy materials. Different types of overhead cranes are suited for various applications, but all share certain elements in common. Generally speaking, most overhead crane systems include a bridge girder or beam that spans the space between two supports, a trolley with hoisting mechanisms mounted on top, and an operator’s cabin or platform from which the crane is controlled. There may also be an auxiliary girder between the endpoints to aid in weight distribution or handle additional loads.

Motorised drives in the bridge and trolley assemblies provide power for lifting operations and moving material along the span. Some overhead cranes can also employ servo motors for tasks requiring precision positioning and cutting operations. Together, these components combine to form a powerful tool for efficiently managing material handling processes on production floors and venues around the globe.