When it comes to industrial equipment maintenance, precision is paramount. Ensuring that your machinery and components are functioning at their best not only improves operational efficiency but also saves on maintenance costs and prevents costly downtime. One crucial technique for achieving this precision is laser alignment. At Jones Complete Services, we understand the vital role that laser alignment plays in industrial maintenance. It’s the key to maximising performance and extending the lifespan of your equipment while reducing the risk of failures or malfunctions. In this article, we will delve into the world of laser alignment, exploring its various applications and how it can benefit your industrial operations.

What is Laser Alignment And Why Your Business Needs It

Machinery Alignment

Laser alignment plays a critical role in machinery alignment. It involves aligning rotating machinery and equipment such as pumps, motors, turbines, compressors, fans, and shafts. The goal is to ensure that all components work together harmoniously, reducing vibration and minimising wear and tear. Proper machinery alignment can significantly extend the life of your equipment and boost its performance, leading to substantial cost savings in the long run.

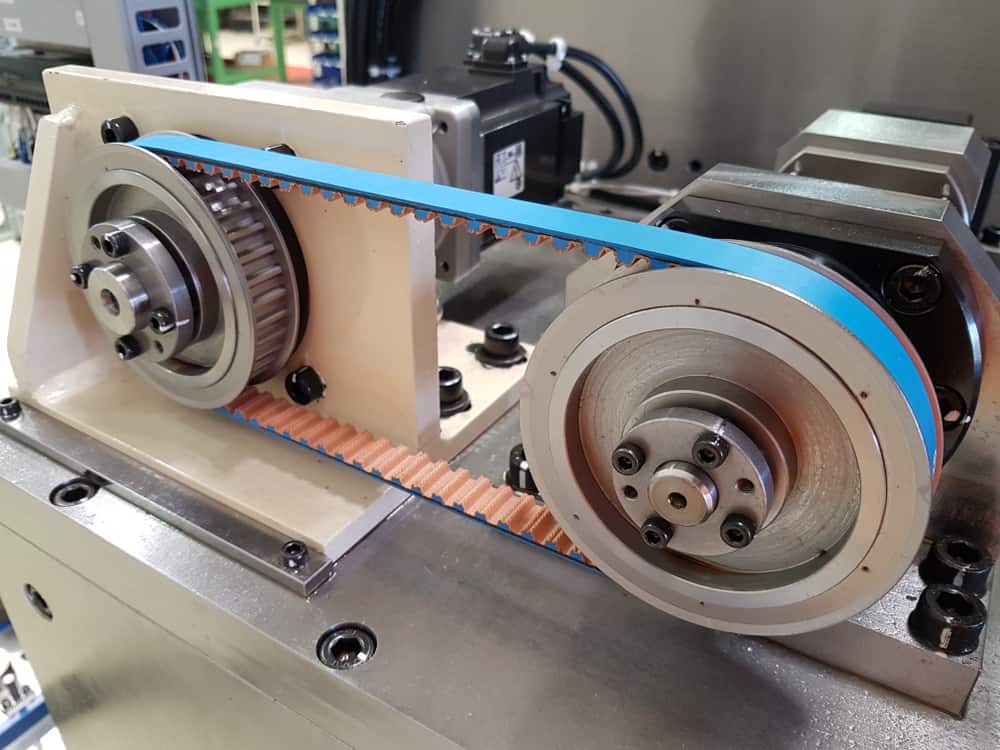

Belt and Pulley Alignment

Belt and pulley systems are prevalent in industrial settings. Misalignment in these systems can lead to increased friction, decreased efficiency, and premature wear and tear. Laser alignment helps to ensure that belts and pulleys are correctly aligned, reducing energy consumption and preventing costly breakdowns.

Coupling Alignment

In industrial processes, couplings are essential for connecting various parts of a system. Misalignment of couplings can result in significant problems, including excessive vibration, reduced power transmission, and equipment damage. Laser alignment is the go-to solution for aligning couplings accurately, ensuring smooth operation and preventing issues associated with misalignment.

Frames, Fixed Plant, and Machine Base Alignment

Laser alignment isn’t limited to just moving parts. It’s also used to align the frames and bases of large industrial equipment. Proper alignment of frames, fixed plants, and machine bases is crucial to maintain the structural integrity of your equipment. Laser technology ensures precise alignment, reducing the risk of uneven loads, structural fatigue, and machinery failure.

Monorail Installation and Alignments

Monorail systems are integral in industrial settings, particularly for moving heavy loads efficiently. Accurate installation and alignment of monorail systems are essential to ensure safety and prevent operational issues. Laser alignment techniques are used to guarantee that monorail systems are installed correctly and aligned with precision, providing a safe and efficient material handling solution.

The Technology Behind Laser Alignment

Laser alignment relies on cutting-edge technology to achieve unparalleled accuracy. It involves the use of laser beams to measure and adjust the alignment of industrial equipment. High-precision instruments emit laser lines that help technicians detect and correct misalignments in real time. This technology ensures that even the slightest misalignment can be identified and corrected, contributing to optimal operational performance.

Laser Alignment – All The Benefits To Consider

The advantages of laser alignment are numerous. Properly aligned industrial equipment experiences reduced wear and tear, resulting in longer lifespans and fewer breakdowns. Also, significantly enhances efficiency, leading to energy savings and increased production output. Additionally, laser alignment contributes to a safer working environment by minimising vibrations and the risk of equipment failure.

Cost Savings and Reduced Downtime

One of the most significant benefits of laser alignment is the cost savings it provides. By preventing premature wear and tear and increasing operational efficiency, laser alignment helps companies save on maintenance and repair costs. It also plays a pivotal role in reducing downtime, as aligned equipment is less likely to experience unexpected failures that could halt

Expert Laser Alignment Services

To harness the full potential of laser alignment for your industrial equipment, it’s essential to enlist the services of experts like Jones Complete Services. Our experienced technicians are skilled in the art of laser alignment and have access to state-of-the-art equipment. We provide comprehensive laser alignment services, ensuring that your industrial machinery and equipment are always in optimal working condition.

Laser Alignment for a Brighter Industrial Future

Laser alignment is an indispensable tool for maintaining the operational efficiency, reducing maintenance costs, and preventing unnecessary downtime of industrial equipment. It encompasses a wide range of applications, from machinery alignment to belt and pulley alignment and beyond. By investing in expert laser alignment services, you can unlock the full potential of your industrial equipment, extend its lifespan, and ensure the continued success of your industrial operations.At Jones Complete Services, we are committed to helping you achieve the benefits of laser alignment. Contact us today to learn more about how laser alignment can transform your industrial processes and keep your equipment operating at its best. Your industrial future is brighter with laser alignment.

How Do You Pick The Right Industrial Equipment Supplier?

Selecting the right industrial equipment supplier, like Jones Complete Services, is a crucial decision that can have a significant impact on your business operations. To make an informed choice, consider the following factors:

Reputation and Experience: Look for a supplier with a solid reputation and a long history of serving the industrial sector. Companies like Jones Complete Services, with a proven track record, are more likely to provide reliable products and services.

Quality of Equipment: Assess the quality of the equipment provided by the supplier. Ensure that they offer high-quality, reliable, and durable industrial equipment that meets industry standards.

Range of Products and Services: Consider your specific industrial equipment needs and ensure the supplier offers a broad range of products and services. This should include not only equipment but also maintenance, repair, and alignment services.

Technical Expertise: An ideal supplier should have a team of highly skilled and experienced technicians who can provide expert guidance, installation, and maintenance support for the equipment they provide.

Customer Support: Evaluate the supplier’s customer support services. A responsive and helpful support team can address your queries and concerns promptly, minimising downtime and operational disruptions.

Customisation Options: Depending on your unique industrial requirements, it’s beneficial to work with a supplier who can customise equipment or solutions to fit your specific needs.

Availability of Spare Parts: Equipment breakdowns are inevitable. Ensure that the supplier offers a readily available supply of spare parts to minimise downtime during repairs.

Cost and Pricing Structure: Consider the pricing structure, including initial costs, maintenance fees, and any additional charges. It’s important to choose a supplier whose pricing aligns with your budget while providing quality equipment and services.

References and Testimonials: Ask for references or read testimonials from other businesses that have worked with the supplier. This can provide valuable insights into their performance and customer satisfaction.

Warranty and Service Contracts: Inquire about warranties and service contracts for the equipment. A good supplier should offer comprehensive warranties and service agreements to ensure the longevity of your investment.

Compliance and Safety: Confirm that the supplier adheres to industry regulations and safety standards. Compliance with safety protocols is essential for the safe operation of industrial equipment.

Location and Accessibility: Consider the supplier’s location and proximity to your business. Having a local supplier can simplify logistics and lead to quicker response times in case of emergencies.

Environmental Considerations: In today’s environmentally conscious world, it’s essential to assess the supplier’s commitment to environmental sustainability, including the eco-friendliness of their products and practices.

Financial Stability: Ensure the supplier is financially stable and has the resources to provide continuous support and services, especially for long-term projects.

Communication and Transparency: Effective communication and transparency in business dealings are crucial. A reputable supplier should be open about their processes, timelines, and any potential challenges.

By thoroughly evaluating these factors, you can make an informed decision when choosing an industrial equipment supplier like Jones Complete Services. Selecting the right supplier ensures that your business operations run smoothly, efficiently, and cost-effectively.

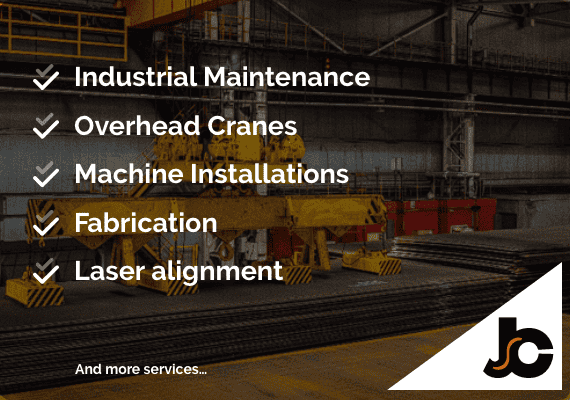

Jones Complete Services understands the vital role of laser alignment in industrial operations. It boosts efficiency, cuts maintenance costs, and prevents downtime. Laser alignment ensures equipment is correctly aligned, extending performance and durability while reducing breakdown risks. Our services include:

- Machinery alignment (e.g., pumps, motors, compressors)

- Belt and pulley alignment

- Coupling alignment

- Frames, fixed plant, and machine base alignment

- Monorail installation and alignment

Get in touch with us to find out more about laser alignment today!