Industrial cleaning is a critical part of maintaining the operational integrity, safety, and hygiene of large-scale commercial and industrial facilities. These encompass a wide spectrum of environments, from factories and warehouses to manufacturing plants, power generation facilities, and intricate refineries. Industrial cleaning is essential for responsible facility management and upkeep, and is different from routine household or office cleaning by the scale, intricacy, and unique challenges inherent to these industrial settings.

This encompasses a range of specialised tasks, tailored to address the needs of these industrial landscapes, ensuring they function smoothly, safely, and in compliance with stringent regulations. We discuss industrial cleaning and the significance it holds across diverse sectors and industries.

What Does Industrial Cleaning Involved;

Specialised Equipment: Industrial cleaning often requires specialised equipment and machinery designed to handle large spaces and heavy-duty cleaning tasks. This may include industrial vacuum cleaners, pressure washers, steam cleaners, scrubbers, and more.

Safety Compliance: Safety is a top priority in industrial cleaning due to the potential hazards present in industrial environments. Cleaning professionals in this field are trained to follow safety protocols and use appropriate personal protective equipment (PPE).

Chemicals and Cleaning Agents: Industrial cleaning may involve the use of industrial-strength cleaning chemicals and agents to remove tough stains, grease, oil, and other contaminants commonly found in industrial settings.

High Cleaning Standards: Industrial facilities often have strict cleanliness standards to maintain, especially in sectors like food processing, pharmaceuticals, and electronics manufacturing, where cleanliness is critical to product quality and safety.

Regular Maintenance: In many industrial settings, cleaning is not a one-time task but an ongoing process. Regular maintenance and cleaning schedules are established to ensure that facilities remain clean, safe, and operational.

Compliance with Regulations: Industrial cleaning may also involve compliance with environmental and regulatory standards. Proper disposal of waste, adherence to environmental regulations, and documentation of cleaning activities are essential aspects of the process.

Skilled Workforce: Industrial cleaning often requires a skilled workforce with training in cleaning techniques, equipment operation, safety procedures, and hazard identification. Some tasks may also require certifications or specialised training.

Customised Cleaning Plans: Cleaning plans for industrial facilities are typically customised to address the specific needs and challenges of each facility. These plans may include daily, weekly, monthly, or periodic cleaning tasks.

Maintenance of Machinery: Industrial cleaning may also involve the cleaning and maintenance of industrial machinery and equipment to ensure they operate efficiently and safely.

Health and Hygiene: In environments where employees work, maintaining a clean and hygienic space is important for the well-being and productivity of workers.

Industrial cleaning plays a crucial role in maintaining a safe and efficient work environment in industrial settings. It helps prevent accidents, reduces the risk of contamination, ensures compliance with regulations, and extends the lifespan of equipment and infrastructure. Industrial cleaning services are often provided by specialised cleaning companies that have the expertise and resources to handle the unique challenges of industrial environments.

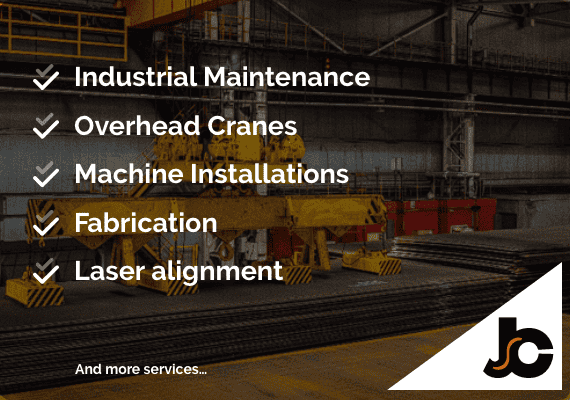

Jones Complete Services & Industrial Cleaning

At Jones Complete Services, we understand the importance of personalised industrial cleaning solutions. Through regular assessments and customised cleaning plans, we help you discover the most efficient cleaning methods for your specific requirements. Our proactive approach minimises unexpected disruptions, ensuring your operations run smoothly and remain uninterrupted.

Our industrial cleaning services cater to diverse sectors, including:

- Food-grade facilities, including wheat, flour, and grain plant equipment.

- Silos.

- Heavy industrial plant equipment.

- General and routine cleaning maintenance services.

How To Clean Food-Grade Facilities, Silo’s, and Heavy Industrial Plant Equipment

Cleaning food-grade equipment, silos, heavy industrial plant equipment, and providing general cleaning and routine maintenance services in industrial settings require specific techniques, equipment, and attention to safety and hygiene. Here’s a general overview of how each of these tasks can be approached:

Food Grade Equipment Cleaning (Wheat, Flour, and Grain Plant Equipment):

- Preparation: Before cleaning, ensure that all equipment is properly shut down and locked out to prevent accidental start-up.

- Dry Cleaning: Remove loose debris, flour, or grain residues using brushes, vacuum cleaners, or compressed air.

- Wet Cleaning: Use food-grade, non-toxic cleaning agents and hot water to clean surfaces. Scrub all equipment surfaces, including conveyor belts, hoppers, and chutes.

- Sanitization: After cleaning, sanitise equipment to eliminate bacteria and pathogens. Use food-grade sanitizers, and follow recommended contact times and dilution ratios.

- Rinse Thoroughly: Rinse all surfaces with clean water to remove any residue from cleaning agents and sanitizers.

- Drying: Ensure that all equipment is thoroughly dried to prevent the growth of mould or bacteria.

Silos Cleaning:

- Safety Measures: Prioritise safety by ensuring confined space entry protocols are followed if necessary.

- Empty Silos: Begin by emptying the silos of all contents.

- Dry Cleaning: Remove loose debris, dust, and contaminants using brushes, vacuum systems, or compressed air.

- Wet Cleaning: Apply appropriate cleaning agents and water to the interior of the silo. Use tools like pressure washers, brushes, or scrapers as needed.

- Sanitization: If the silo is used for food storage, follow food-grade sanitization protocols.

- Thorough Rinse: Ensure thorough rinsing of the silo to remove cleaning agents and sanitizers.

- Drying: Allow the silo to dry completely before refilling it.

Heavy Industrial Plant Equipment Cleaning:

- Safety First: Prioritise safety by following lockout/tagout procedures and wearing appropriate PPE.

- Dry Cleaning: Remove loose debris, grease, and contaminants using brushes, scrapers, or industrial vacuum systems.

- Wet Cleaning: Apply suitable industrial cleaning agents, degreasers, or solvents to tackle heavy-duty stains and grime.

- Pressure Washing: For large equipment, pressure washing can be effective in removing stubborn dirt and contaminants.

- Rinse and Dry: Thoroughly rinse all surfaces to remove cleaning agents and contaminants, and ensure equipment is dry to prevent corrosion.

General Cleaning and Routine Maintenance Services:

- Establish a cleaning schedule that includes daily, weekly, and monthly tasks.

- Use appropriate cleaning agents and equipment for different surfaces and areas.

- Focus on high-traffic and high-touch areas.

- Pay attention to safety by addressing potential hazards and maintaining safety protocols.

- Regularly inspect equipment for signs of wear and tear, and perform routine maintenance as needed.

In all cases, documentation of cleaning activities, adherence to regulatory requirements, and ensuring the safety of personnel are essential aspects of industrial cleaning. Additionally, it’s crucial to use cleaning agents and methods that are compatible with the specific materials and processes involved in each industrial setting, especially in food-grade environments where hygiene standards are paramount. Consulting with experts in industrial cleaning and compliance with industry-specific guidelines and regulations is recommended.

Why High-Quality Industrial Cleaning Is So Important For Your Commercial Business

Industrial cleaning is of paramount importance for several reasons, as it plays a crucial role in maintaining the safety, efficiency, and overall functionality of industrial facilities. Here are some key reasons why industrial cleaning is essential:

Worker Safety: Clean and well-maintained industrial environments reduce the risk of accidents and injuries. Regular cleaning removes hazards like oil spills, debris, and slippery surfaces, making the workplace safer for employees.

Product Quality: In industries such as food processing, pharmaceuticals, and electronics manufacturing, cleanliness is critical to product quality. Failure to maintain a clean environment can lead to contamination, defects, and product recalls.

Equipment Longevity: Industrial equipment and machinery are expensive investments. Proper cleaning and maintenance extend their lifespan, reduce downtime, and lower the overall cost of ownership.

Efficiency: Clean machinery and equipment operate more efficiently. Reduced friction, improved airflow, and less wear and tear contribute to increased productivity and energy efficiency.

Compliance with Regulations: Many industries are subject to strict regulations and hygiene standards. Industrial cleaning is necessary to ensure compliance with local, state, and federal regulations, as well as industry-specific standards.

Environmental Responsibility: Proper disposal of waste and the use of environmentally friendly cleaning agents contribute to sustainability efforts and reduce the environmental impact of industrial operations.

Prevention of Contamination: In industries dealing with chemicals, pharmaceuticals, or food products, contamination can have serious consequences. Regular cleaning helps prevent cross-contamination and ensures the purity of products.

Maintenance of Reputation: A clean and well-maintained industrial facility enhances a company’s reputation. It instals confidence in customers, investors, and regulatory authorities.

Operational Continuity: Industrial cleaning includes routine maintenance tasks that can identify potential issues before they become major problems. This proactive approach helps ensure operational continuity and reduces the risk of unexpected breakdowns.

Health and Well-being: A clean working environment promotes the health and well-being of employees. It reduces exposure to allergens, dust, and harmful substances, leading to improved employee morale and productivity.

Fire Prevention: Dust and debris buildup can pose fire hazards, especially in industrial settings with flammable materials. Regular cleaning minimises the risk of fires and explosions.

Cost Savings: While industrial cleaning does incur costs, it often results in cost savings in the long run. Preventative maintenance and a clean environment reduce repair and replacement costs and improve overall efficiency.

Quality Control: Cleaning often involves inspecting equipment and systems for defects or irregularities. This quality control process helps identify and address issues early, preventing potential product defects or process failures.

Industrial cleaning plays a pivotal role in upholding the safety, productivity, and regulatory adherence of industrial facilities. It not only safeguards the well-being of workers and the quality of products but also serves as a linchpin for the enduring prosperity of industrial enterprises. Overlooking or underestimating the importance of industrial cleaning can result in substantial repercussions, encompassing accidents, non-compliance with regulations, and harm to a company’s image and standing. Book industrial cleaning with JCS today!